Introduction to Concurrent Engineering Concurrent engineering (CE) is a method that is used in the product development process. Concurrent Engineering, sometimes called Simultaneous Engineering or Integrated Product Development (IPD), can be defined as a systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support. It is different than the traditional approach from the product development in which it uses simultaneous, something that sequential, processes. By finishing the tasks in paralelamente, the product development can be obtained more efficiently and in substantial saving in costs. In the traditional approach finishing all the physical manufacture of a prototype before realizing any test, but In the concurrent engineering it allows to design and multiple analyses to happen at the same time, and at different times, before the real unfolding. This multidisciplinary approach accentuates work in equipment with the use of cross-functional equipment, and allows so that Continue reading

Operations Management

Deming’s System of Profound Knowledge – 14 Principles

William Edwards Deming (1900-1993) was a renowned American quality management consultant, professor, and statistician, and wrote several books on product quality and management and gave lectures on the same. He is attributed for helping to advancement in production in corporate America but his greatest achievements were in Japan. He made a major contribution to Japan’s a trade and industry development, and also the advancement of their high-quality products. Deming (1990) noted that “by adopting appropriate principles of management, organizations could increase quality and simultaneously reduce costs (by reducing waste, rework, staff attrition and litigation while increasing customer loyalty).” Deming recommended that organizations should focus on quality which leads to reduction of costs, instead of concentrating on costs that decrease the quality gradually. He mostly advocated for proper management as he argued that it was responsible for 85% of the problems that companies face. He argued that good management of an Continue reading

Quick Response Manufacturing (QRM) – Meaning, Principles, Benefits, and Drawbacks

Quick Response Manufacturing (QRM) is a strategy which needs to applied throughout the company and whose primary goal is the reduction of lead-time in each and every operation of the company while simultaneously reducing costs and improving quality. QRM can be defined in two contexts: (i) Externally (Customers point of view): QRM means quickly responding to customer needs by designing and producing goods customized to cater those needs. (ii) Internally, QRM stresses on reducing the lead times throughout the organization, leading to lower inventory, better quality, reduced cost, and greater responsiveness. Quick Response Manufacturing (QRM) uses Manufacturing Critical-path Time (MCT) as the metric for measuring the success of QRM processes. MCT is an extension of the concept of lead-time, which is the time from the receipt of order from the customer till the product is delivered to the customer. There are 2 ways of implementing QRM: one is using large Continue reading

Rummler-Brache Process Improvement Methodology – 9 Boxes Model

From their best seller Improving Performance: How to Manage the White Space on the Organization Chart, Rummler-Brache Process Improvement Methodology draws inspiration from Gilbert’s Behavioral Engineering Model and its understanding of the interdependency of performance and the environment. According to Rummler-Brache Process Improvement Methodology: Addresses performance in a comprehensive, rather than “piecemeal” fashion. Focuses on the 9-variables that represent management’s performance improvement levers. Presents tools rather than mere theory or model of performance. Demystifies the connection between human performance and organizational performance. Provides a basis for optimism: the challenge can be met. The Rummler-Brache Process Improvement Methodology is comprised of three levels of performance; organizational, process and job/performer; and three performance dimensions; goals, design and management. This model forms nine variables in a structured manner, examining human performance in an organizational system. The Three Levels of Performance: Consists of monitoring performance at Job/Performer level, Process Level and Organizational level. These three levels are intricately depended on each other. Any Continue reading

The Deming Prize – Philosophy, Assessment Criteria, and Benefits

The Deming Prize, named after Dr. W. Edwards Deming, was established in 1951. To reconstruct Japan’s economy after WWII, the Japanese government encouraged the formation of industrial organizations. This initiative resulted in the formation of the Union of Japanese Scientists and Engineers (JUSE). JUSE gathered experts and executives from Japan’s key sectors to achieve this goal by exchanging best practices for quality improvement. Dr. Deming was named an expert by JUSE to educate and coach executives, engineers, and academics in the industrial sector on quality control following his commissioning by the United States Army to help with Japan’s postwar enumeration. His strategies were extensively adopted, culminating in greater production, enhanced quality, and cost savings. As a result of the worldwide awareness of the excellent quality attributed to Japanese goods, demand increased. Deming’s Philosophy The award recognizes achievement in comprehensive quality management and is given to people or organizations who effectively Continue reading

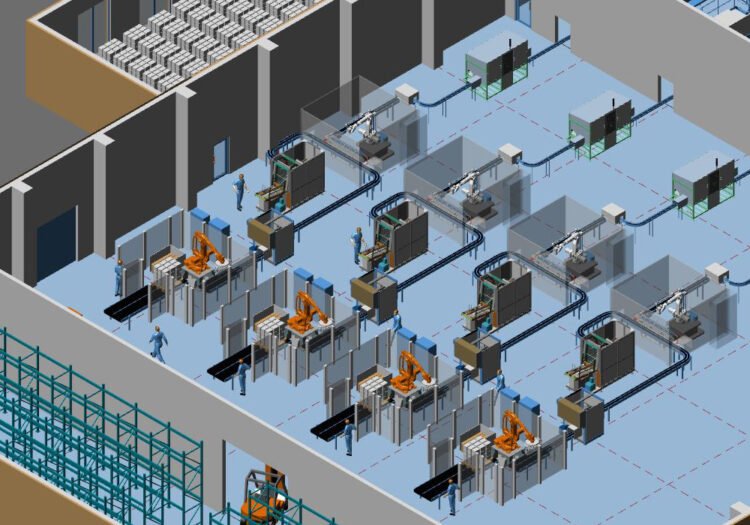

Plant Layout Crtierias and Basic Designs

The layout of a plant or facility is concerned with the physical placement of resources such as equipment and storage facilities, which should be designed to facilitate the efficient flow of customers or materials through the manufacturing or service system. The layout design is very important and should be taken very seriously as it can have a significant impact on the cost and efficiency of an operation and can involve substantial investment in time and money. The decisions taken with regards to the facility layout will have a direct influence on how efficiently workers will be able to carry out their jobs, how much and how fast goods can be produced, how difficult it is to automate a system, and how the system in place would be able to respond to any changes with regards to product or service design, product mix, or demand volume. In many operations the installation Continue reading