“Machines alone do not give us mass production. Mass production is achieved by machines and men.” – Henry Ford II ,1914 Above quote which said by Henry Ford, it doesn’t mean that human alone cannot achieve mass productions but with machines, mass productions can be easily achieved with the right machines. Computer-controlled, intelligent assist devices are a huge change in material handling technology today. The step changes in their ergonomics, productivity, quality and safety capabilies – especially when compared with tradition pneumatic tools which are considered old schooled in compared with cobots today. Cobots, or collaborative robots, are robots intended to interact with humans in a shared space or to work safely in close proximity. Cobots stand in contrast to traditional industrial robots which are designed to work autonomously with safety assured by isolation from human contact. Cobot safety may rely on lightweight construction materials, rounded edges, and limits on speed Continue reading

Production Management

The Pareto Principle Explained (The 80/20 Rule)

What is the Pareto Principle? Vilfredo Federico Damaso Pareto was an Italian economist, he discovered that in any situation twenty percent of the inputs/activities are responsible for eighty percent of the outputs/results. In 1906, he discovered that 80% of the land in Italy was owned by only 20% of the people. Later he recognized that same lop-sided relationship applied to other things as well. Pareto first discovered this law in his own garden. He noticed that twenty percent of his pea pods, created eighty percent of the peas, as an economist he then drew parallels to Italy’s economy, discovering that eighty percent of the land belonged to twenty percent of the population. Pareto’s Principle basically states that a small number of reasons are responsible for a large percentage of the effect; this ratio is usually 20% of the cause to 80% of the effect, or 20:80. However, this principle was Continue reading

Concurrent Engineering (CE) – Definition, Approaches and Requirements

Introduction to Concurrent Engineering Concurrent engineering (CE) is a method that is used in the product development process. Concurrent Engineering, sometimes called Simultaneous Engineering or Integrated Product Development (IPD), can be defined as a systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support. It is different than the traditional approach from the product development in which it uses simultaneous, something that sequential, processes. By finishing the tasks in paralelamente, the product development can be obtained more efficiently and in substantial saving in costs. In the traditional approach finishing all the physical manufacture of a prototype before realizing any test, but In the concurrent engineering it allows to design and multiple analyses to happen at the same time, and at different times, before the real unfolding. This multidisciplinary approach accentuates work in equipment with the use of cross-functional equipment, and allows so that Continue reading

Quick Response Manufacturing (QRM) – Meaning, Principles, Benefits, and Drawbacks

Quick Response Manufacturing (QRM) is a strategy which needs to applied throughout the company and whose primary goal is the reduction of lead-time in each and every operation of the company while simultaneously reducing costs and improving quality. QRM can be defined in two contexts: (i) Externally (Customers point of view): QRM means quickly responding to customer needs by designing and producing goods customized to cater those needs. (ii) Internally, QRM stresses on reducing the lead times throughout the organization, leading to lower inventory, better quality, reduced cost, and greater responsiveness. Quick Response Manufacturing (QRM) uses Manufacturing Critical-path Time (MCT) as the metric for measuring the success of QRM processes. MCT is an extension of the concept of lead-time, which is the time from the receipt of order from the customer till the product is delivered to the customer. There are 2 ways of implementing QRM: one is using large Continue reading

Plant Layout Crtierias and Basic Designs

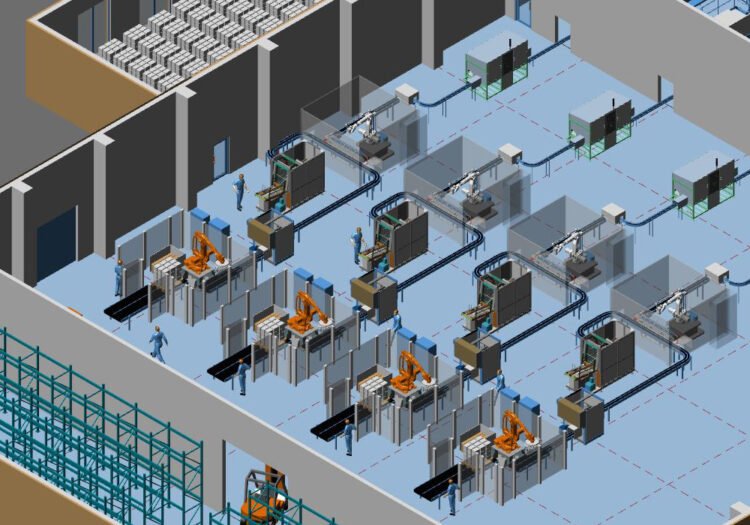

The layout of a plant or facility is concerned with the physical placement of resources such as equipment and storage facilities, which should be designed to facilitate the efficient flow of customers or materials through the manufacturing or service system. The layout design is very important and should be taken very seriously as it can have a significant impact on the cost and efficiency of an operation and can involve substantial investment in time and money. The decisions taken with regards to the facility layout will have a direct influence on how efficiently workers will be able to carry out their jobs, how much and how fast goods can be produced, how difficult it is to automate a system, and how the system in place would be able to respond to any changes with regards to product or service design, product mix, or demand volume. In many operations the installation Continue reading

Work Study – Meaning, Importance and Procedure

Work Study forms the basis for work system design. The purpose of work design is to identify the most effective means of achieving necessary functions. Work study aims at improving the existing and proposed ways of doing work and establishing standard times for work performance. Work design involves job design, work measurement and the establishment of time standards and worker compensation. Work Study is encompassed by two techniques -method study and work measurement (time study): Method study is the systematic recording and critical examination of existing and proposed ways of doing work, as a means of developing and applying easier and methods and reducing costs. The main purpose of method study is to eliminate the unnecessary operations and to achieve the best method of performing the operation. Method study is also called methods engineering or work design. Method engineering is used to describe collection of analysis techniques which focus on improving Continue reading