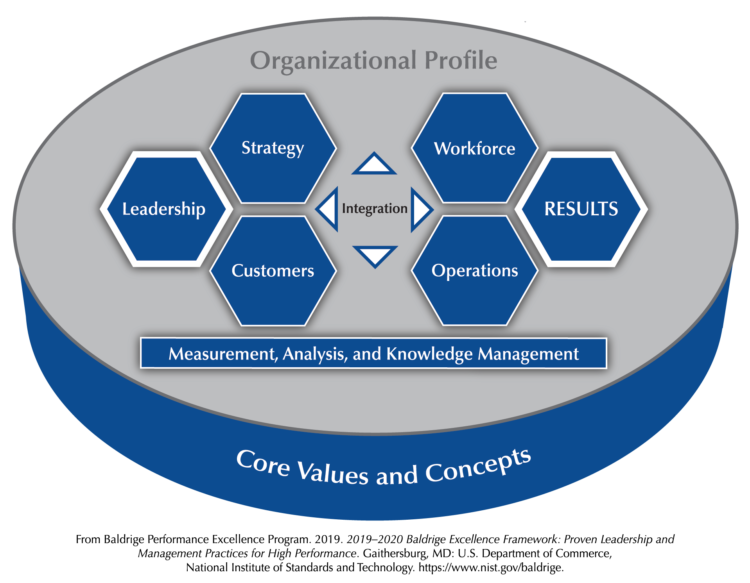

In the business world, the realization of business excellence is pivotal towards fostering the success of an enterprise. In this respect, business organizations need to engage in actions that facilitate performance excellence. The areas of business operations that need a considerable extent of excellence include customer satisfaction, workforce fulfillment, operations efficiency, and business growth. The need for continuous improvement influences business managers to adopt the suitable performance excellence models. The Baldrige Excellence Framework is one of the most sought-after performance excellence models that drive the success of businesses in different sectors. The model mainly focuses on bolstering performance excellence by improving the business aspects of leadership, strategic planning, customer supervision, workforce administration, knowledge management, and operations focus. Business organizations need to focus on improving the performance of the mentioned aspects to realize significant excellence in their respective industries. Background In the mid-1980s, leaders in the United States saw the need Continue reading

Quality Management

Comparing Six Sigma and Total Quality Management (TQM)

Six Sigma Six Sigma is the management technique based on project development and improving critical services and products of a firm. Therefore, Six Sigma aims to reduce product defects, reduce maintenance costs, and increase production effectiveness and efficiency to achieve these improvements. The techniques also aim at improving the understanding and satisfaction of clients’ needs and corporate governance by enhancing the competitive advantage of firms. The mechanism improves productivity and a company’s financial performance by establishing measures of correcting an organization’s internal controls. The primary aim of the Six Sigma mechanism is to improve the firm’s process capabilities by using various statistical tools. It reduces waste and eliminates costs that do not add value to the firm’s performance. The main objective of this technique is to improve service delivery and enhance customer satisfaction after correcting the critical business process which would cause delays in their performance. When the importance of Continue reading

Deming’s System of Profound Knowledge – 14 Principles

William Edwards Deming (1900-1993) was a renowned American quality management consultant, professor, and statistician, and wrote several books on product quality and management and gave lectures on the same. He is attributed for helping to advancement in production in corporate America but his greatest achievements were in Japan. He made a major contribution to Japan’s a trade and industry development, and also the advancement of their high-quality products. Deming (1990) noted that “by adopting appropriate principles of management, organizations could increase quality and simultaneously reduce costs (by reducing waste, rework, staff attrition and litigation while increasing customer loyalty).” Deming recommended that organizations should focus on quality which leads to reduction of costs, instead of concentrating on costs that decrease the quality gradually. He mostly advocated for proper management as he argued that it was responsible for 85% of the problems that companies face. He argued that good management of an Continue reading

The Deming Prize – Philosophy, Assessment Criteria, and Benefits

The Deming Prize, named after Dr. W. Edwards Deming, was established in 1951. To reconstruct Japan’s economy after WWII, the Japanese government encouraged the formation of industrial organizations. This initiative resulted in the formation of the Union of Japanese Scientists and Engineers (JUSE). JUSE gathered experts and executives from Japan’s key sectors to achieve this goal by exchanging best practices for quality improvement. Dr. Deming was named an expert by JUSE to educate and coach executives, engineers, and academics in the industrial sector on quality control following his commissioning by the United States Army to help with Japan’s postwar enumeration. His strategies were extensively adopted, culminating in greater production, enhanced quality, and cost savings. As a result of the worldwide awareness of the excellent quality attributed to Japanese goods, demand increased. Deming’s Philosophy The award recognizes achievement in comprehensive quality management and is given to people or organizations who effectively Continue reading

Kaizen Vs Six Sigma: What’s the Difference?

The significance of a positive change is intrinsically characteristic of any culture. However, when viewed through the lens of a specific set of traditions, philosophies and the world picture, the phenomenon shapes, gaining new shades of meaning and incorporating more wisdom. Although kaizen, which is the Japanese interpretation of the continuous improvement concept, originates from a culture strikingly different from the Western one, in general, and the American one, in particular, it rubs shoulders with the Six Sigma concept as the foundation for an unceasing change toward the changing concept of perfection. The concept of improvement, which both Six Sigma and kaizen are meant to be geared toward, evidently is the characteristic that brings the two notions together. Diving deep into the Japanese philosophy of kaizen, one must mention that it implies little changes done reliably over a drawn out stretch of time. In other words, the focus on the Continue reading

Maximizing Productivity through Lean Thinking and Just-In-Time (JIT)

Companies aim to improve their productivity and increase their profitability. Consequently, many firms adopt effective strategies and business models that enhance their operations. Lean Thinking and Just-In-Time (JIT) models help maximize their efficiency and viability. Lean thinking involves a transformational framework that organizes human activities to deliver value to human beings while eliminating waste. Meanwhile, JIT is an inventory model that allows goods to be received from suppliers only as they are needed. The rationale for companies adopting JIT is to reduce inventory holding costs and increase inventory turnovers. Therefore, Lean thinking and JIT are significant among businesses since they help reduce costs and promote business productivity. The lean thinking framework has been adopted by many companies and has proved successful in various industrial dimensions. James Womack and Daniels Jones first used the term. The concept integrates five principles that contribute to its success: value, value stream, flow, pull, and Continue reading