In the current competitive business environment, the success of a firm is partly determined by the strategies it uses in managing procurement and supply chains. One of the ways of ensuring that a firm gets the best value in its procurement and supply chain is to use effective negotiation strategies. Negotiation is defined as a process in which two or more people with differing views, reach agreement by the use of different methods of persuasion. A negotiation process can only be considered a success if the two parties reach an agreement. Not all negotiations often end up in an agreement. However, if the parties can agree on the contentious issues involved, then the process is considered completed. Acquiring raw materials from suppliers is a process that requires negotiation. While the supplier may try to get as much profit from the supplies as possible, the buyer would want to purchase the Continue reading

Supply Chain Management

Developing Contracts in Procurement and Supply

Driving value through procurement and supply is the aim of every firm that has mastered the market forces. Such firms know that quality of the products they deliver to their customers and the price they shall charge all depend on their procurement strategies. As such, it is important to develop techniques that can be used in acquiring raw materials to improve the benefit, especially when the implementation is to be done in the future. The management should know the inclusions that should be made in the contract and measures that should be taken to ensure that changes in the market forces do not affect the agreements made in the contract. Effective management of the supply chain can help reduce the cost of production and in increasing value for the customers. Inclusions that should be Made in Procurement and Supply Contracts Developing contracts is one of the most complex processes that Continue reading

Building a Sustainable Supply Chain Through Triple Bottom Line (TBL)

Sustainability is an important aspect of business in modern society where environmental pollution, economics, efficiency, effectiveness, and conservation of energy are issues of concern. As a distribution network that organizations rely on distributing their diverse products, the supply chain has a significant impact on the environment. In this view, the supply chain should be sustainable for it to serve varied organizations optimally and experience growth in the competitive markets. Sustainability is beneficial to the supply chain because it reduces costs, decreases wastage, improves efficiency, saves energy, and enhances competitive advantage. Governments and customers also increase pressure on the supply chain to adopt strategies that are sustainable to protect not only the environment but also encourage prudent use of available resources. Recycle, reuse, reduce, and recover are the four principles, which promote sustainability of operations in the supply chain. In essence, the sustainability of the supply chain is central to improving Continue reading

Reverse Logistics Process Formalization

Reverse logistics is the process of planning, implementing and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing or creating value or for proper disposal. Despite the growing recognition of the importance of reverse logistics, many companies are not ready to meet the challenges involved in handling returns. The rapid growth in the volume of returns far outpaces the abilities of firms to successfully manage the returns. Because of all the uncertainties involved, reverse logistics program development and implementation becomes very complex. The major challenges involve the considerable number of unknowns that have to be accounted for in developing reverse logistics programs. The process of measuring and analyzing returns-related performance criteria is aimed at improving reverse logistics quality and identifying potential problem areas. The following metrics were identified by Continue reading

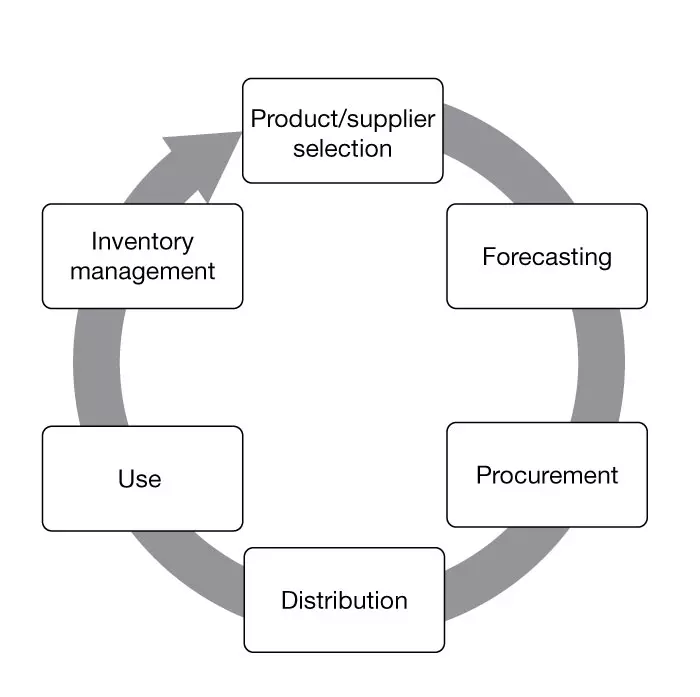

Components of Supply Chain

A supply chain is a network of manufacturers, suppliers, distributors, transporters, storage facilities and retailers that perform functions like procurement and acquisition of material, processing and transformation of the material into intermediate and finished tangible goods, and finally, the physical distribution of the finished goods to intermediate or final customers. Major Components of Supply Chain A supply chain may consist of variety of components depending on the business model selected by a firm. A typical supply chain consists of the following components: Customers: The customer forms the focus of any supply chain. A customer activates the processes in a supply chain by placing an order with the retailer. The customer order is filled by the retailer, either form the existing inventories, or by placing a fresh order with the wholesaler/manufacturer. In some cases a customer bypasses all these supply chain components by getting in touch with the manufacturers directly. For Continue reading

Supply Chain Performance Measurement

The main objective of performance measurement is to provide valuable information which allows firms to improve the fulfillment of customers’ requirements and to meet firm’s strategic goals. It is therefore important to measure how effectively the customers’ requirements are met and how resources are efficiently used to reach a certain level of customer satisfaction. Supply chain performance measurement is used to evaluate the effectiveness and efficiency of organizational structures, processes and resources not only for one firm but also for the entire supply chain. It provides some basis for understanding the whole system, influence the behavior and supply information about the performance of the supply chain participants and stakeholders. Developing and using performance measures is an essential function of management. The usage of performance measurement systems also supports the objectives of transparency and a mutual understanding of the whole supply chain. Supply Chain Controlling One of the main tasks of Continue reading