In the current competitive business environment, the success of a firm is partly determined by the strategies it uses in managing procurement and supply chains. One of the ways of ensuring that a firm gets the best value in its procurement and supply chain is to use effective negotiation strategies. Negotiation is defined as a process in which two or more people with differing views, reach agreement by the use of different methods of persuasion. A negotiation process can only be considered a success if the two parties reach an agreement. Not all negotiations often end up in an agreement. However, if the parties can agree on the contentious issues involved, then the process is considered completed. Acquiring raw materials from suppliers is a process that requires negotiation. While the supplier may try to get as much profit from the supplies as possible, the buyer would want to purchase the products at the least possible price. These conflicting views must be addressed to make the two parties sign a contract acceptable to both of them. The management must ensure that the firm gets the needed materials within the right time and in the right quantity.

Roles of Procurement and Supply in Managing the Area of Expenditure

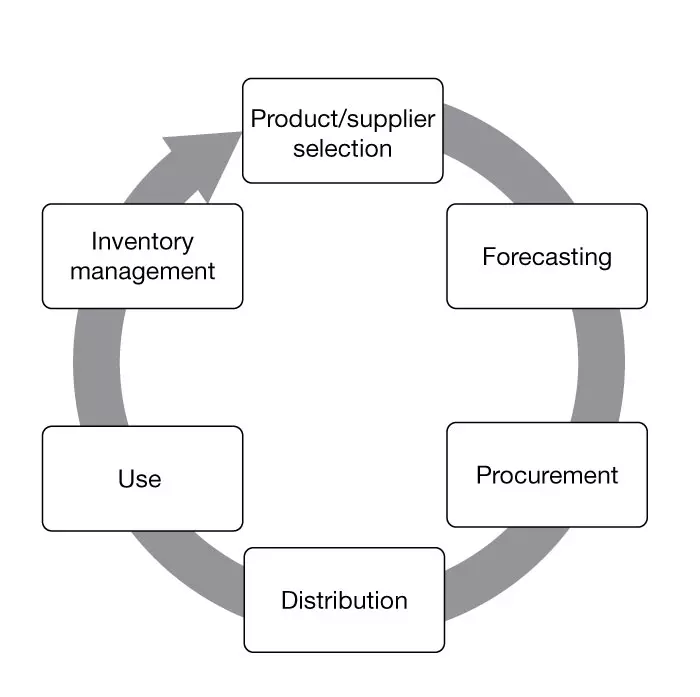

Acquiring raw materials is one of the most important stages in value chain management. The approach used in acquiring the raw materials often defines the cost and quality of the final product. Managing expenditures when acquiring these materials is, therefore, of great importance. It is for this reason that it is necessary to evaluate the roles of procurement and supply in managing this area of expenditure. Procurement and supply is defined as an area of management that involves buying of goods and services to enable a firm to operate. It entails sourcing raw materials from various parts of the world and making them available for production. The following figure shows the stages that should be taken into consideration by the management when sourcing raw materials.

The process starts with need identification. In this case, it is understood that the need will arise in the future, but there is a need to make plans on how these future needs will be met. As such, the whole process should begin with a selection process. When making the plans for future requirements, the management must understand that it is important to select an organization that is most qualified in delivering the best value in the market. Several factors should be taken into consideration in this selection process. The first factor is how well a supplier can provide the needed product. It means that a firm will have to conduct a review of the current suppliers to ensure that they can deliver the raw materials of the highest quality.

The procurement officers may need to go beyond the brand when evaluating the suppliers. Decisions should be made based on the quality offered, not the popularity of the brand. The second factor is the sustainability of the operations of the supplier. As stated, the planning at this stage is for the future, not current needs. As such, the firm to be selected must be in existence in the future when its services shall be needed. It is not possible to be completely certain about the future existence of the suppliers. However, their past and present records can help determine chances that they may still be available in the future to offer the needed products. Issues such as the ability of the supplier to provide the needed quantity should also be taken into consideration when selecting the supplier. At this stage, procurement and supply will help the firm to identify the most qualified supplier that will offer the best value at the least possible cost.

The next stage involves forecasting. When making sourcing plans for future requirements, various stakeholders should help in forecasting to ensure that a correct decision is made in the entire procurement and supply cycle. The market forces keep on changing and prices of the products and supplies keep on fluctuating based on these forces. It is always in the interest of a firm to ensure that its prices on the products offered to the customers remain as stable as possible. The stability of products’ prices helps in eliminating negative reactions among clients and helps fight the perception that they are being exploited. Various stakeholders will be responsible for the forecasting process. The marketing manager and the entire team in the marketing department at organization will need to help predict the future relevance of a product and possible reduction or increase in its price. The product may be irrelevant soon based on the changing tastes and preferences. If that is the case, it may not be necessary to set huge resources for the product when making the plan because it has no future.

Information is critical in the decision-making process in the procurement and supply cycle. The procurement manager and his or her entire team at organization will also have to be involved in the forecasting process. This team will help in determining the future availability of the needed raw materials. They will help determine if the material will be available in the future or not so that a decision can be made early enough to avoid shortages and cut down costs of procurement. The team can also help in determining whether the price of the raw materials may go up or not. When it is established that the price of these materials may drastically increase in the future, then it may be in the interest of the firm to purchase the items early enough as long as they can last long enough to be used when the time comes. The finance officer, the insurance manager, and other senior managers are other important stakeholders who should also be involved in the forecasting process to ensure that the decision made is acceptable to all the stakeholders.

When the forecasting has been made, the next step is procurement. As stated in the stage above of forecasting, the most important decision that the top managers at organization will make is either to purchase the item today and keep it for future use or wait and make the purchase in the future. If the decision is made that the purchase will be made in the future, then planning shall end at that stage. However, if it is considered that it is necessary to proceed with the process, then the team may need to proceed and acquire the needed raw materials. In most cases, such a decision is made when it is determined that the items needed may be more expensive or scarce in the future in a way that their demand will outweigh the supply. The team will need to ensure that they get the best products from the suppliers at the best price possible.

After acquiring the products, the team will need to distribute and store them for future use. It is always in the interest of a firm to ensure that raw materials spend the least possible time in the warehouse. This is so because the longer they spend in the warehouses, the more they become costly to manage. Breakage and pilferage are some of the factors that inflate the cost of these materials when they are in the warehouse. Some products may become stale when kept for a long time in the warehouses. The decision to make early purchases can only be made if it becomes apparent that the overall cost of warehousing the products is less than if the products were to be purchased in the future.

The used inventory management is the final stage in this cycle. At this stage of planning, the team can only make suggestions on how the process should be conducted, but futuristic changes may require changes in the plan in line with the prevailing environmental forces. The most appropriate action at this stage will be to let the team involved to decide when the time comes, whether it will be necessary to change the current pattern of inventory management or not based on the realities that they will be facing in the future. It is, therefore, very clear that procurement and supply will provide the team with a clear pattern on how to behave to ensure that the best outcome is achieved when creating a sourcing plan for future requirements.

Techniques that can be Applied to Improve Added Value in Procurement and Supply

Driving value through procurement and supply is the primary aim of this plan. The aim is to ensure that this firm can meet its future needs in the best way possible and use the least resources. For this to happen, the team involved must have proper negotiation skills that will give it an advantage and ensure that it signs a contract that is beneficial to it. The team should start by first understanding the stages involved in the negotiation process. The figure below shows the fundamental stages of negotiation.

As shown in the above figure, it all starts with preparation and planning. In this context, the firm will need to plan how it will negotiate with the suppliers that will offer it the needed materials. The team responsible for procurement should clearly understand the power of suppliers. The next step is to define the ground rules. At this stage, the two teams come together and set the rules and regulations that shall govern the negotiation process. Fairness is very important at this stage. Both teams must uphold integrity to ensure that they can develop trust with each other. Neither the supplier nor this firm should feel that the rules are set to purpose out-muscle them.

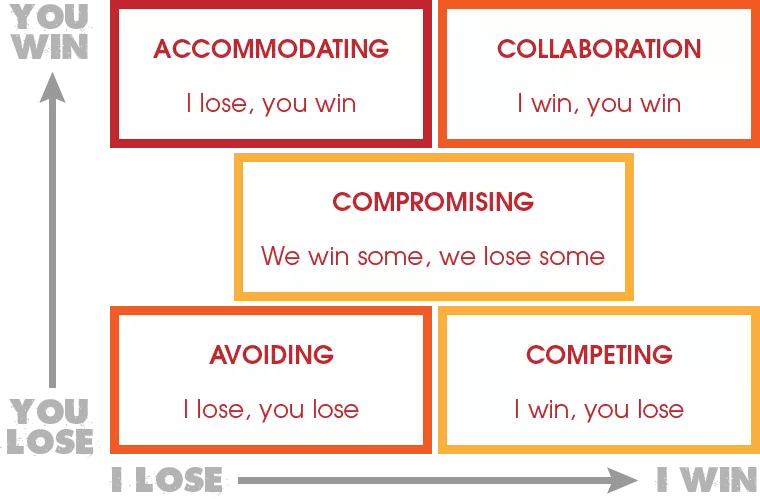

After setting the rules, the next stage will be clarification and justification. Each of the parties involved in the procurement process will be offered the opportunity to present the arguments and the terms they feel are fair. Value creation for this firm starts at this point. The team assigned this role should give a passionate and articulate definition of the need to sign the contract at given terms and conditions. The justification should not be seen to be self-centered because that may bring an intense argument. The team must be very convincing and the other party should feel that its interest has been taken into consideration. The next stage of bargaining and problem solving is very critical. The two parties will be making counterarguments to ensure that the final decision is as favorable to them as possible. The procurement officers at organization should be keen on ensuring that through such negotiations, this company gets the best value in terms of price, quality, and quantity of the raw materials. Sometimes the negotiation may ground to a halt if the parties do not employ proper strategies that will be acceptable. Using Kilmann’s conflict-handling styles, the team responsible for the negotiation for this firm can choose any of the five options. The chosen option should be that which offers improved added value. The figure below shows the model.

Based on the importance of the relationship between the firm and the supplier, and the significance of the outcome, the team can choose any of the five options shown in the model above. The best option is often the collaboration approach. This is a deliberate attempt by the two parties to ensure that they both come out winners in the negotiation process. The firm can convince the supplier to collaborate with it and benefit from its success in the market. Sometimes one or both parties may consider collaboration as an impossible option given the prevailing circumstances. If that is the case, then the next best option would be compromising. Each of the two parties will appreciate the need to make some concessions to reach a common ground. Although the parties will not get what they exactly expected, they will come out with something valuable from the final deal that shall be made.

Under these conditions, this firm will be accepting to lose just for the sake of making the process a success. It will be making an agreement knowing very well that the supplier has come out as the winner of the process. Although it is undesirable, this strategy may be necessary in cases where the supplier has very high negotiating power and the materials it offers are not easily available in the market. In case the firm has other suppliers that can offer the same materials at better terms, then competing may be considered an appropriate option. It means that the firm will force the supplier to stick to its terms and conditions. The supplier will be offered the option of either taking the deal offered or cancellation of the entire process. The fifth option, which is the least desirable one, occurs when the negotiation is grounded. It takes place when both teams agree that the outcome of the negotiation is very important to them, but fails to agree on the terms and conditions of the deal. The team must understand that such a situation may occur, but the problem is that it does not earn the firm the much-needed value.

Thus, procurement and supply chain management is very the most important strategic responsibilities of top managers. These processes help a firm in accessing the raw materials needed for production. It is normal to have situations the suppliers and the buyers have varying opinions. Each will be trying to get the best deal from the engagement. As such, the supplier will try to charge high prices and avoid any additional expenses. On the other hand, the buyer will be demanding very low prices and additional after-sale services. These differences can only be addressed through effective win-win discussions. As a firm tries to acquire materials for its operations, it is necessary to ensure that it maintains good relations with its suppliers. The suppliers should not feel exploited by this company, even in cases where this firm is dealing with small and less powerful suppliers.